Introduction

Flame resistance and flame retardancy are commonly used when discussing fire safety and protection. While they may seem interchangeable, it is crucial to understand the subtle yet significant differences between them. Fire accidents can have devastating consequences, and having a clear comprehension of these terms can help individuals make informed decisions regarding their safety measures.

This article will look into the distinctions between flame resistance and flame retardancy, shedding light on their definitions, characteristics, and applications. Furthermore, we will address a common misconception surrounding these terms by exploring whether they are truly interchangeable.

Definition of Flame Resistance and Flame Retardancy

Let us first establish their definitions to comprehend the differences between flame resistance and retardancy.

Flame resistance refers to the ability of a material to withstand combustion or resist catching fire when exposed to an ignition source. Such materials possess inherent qualities that prevent flames from spreading rapidly or self-extinguishing upon removal of the ignition source.

On the other hand, flame retardancy refers to the capacity of a material to slow down or inhibit the spread of flames when treated with specific chemicals known as flame retardants. These chemicals impede combustion by creating a barrier between the material and the heat source or releasing gases that suppress combustion.

Common Misconception: Are They the Same?

One common misconception is that flame resistance and flame retardancy are synonymous terms for describing fire-resistant materials or products. However, this assumption oversimplifies the distinction between these concepts.

While both aim to enhance fire safety, they differ significantly in their underlying mechanisms and applications. Unlike flame resistance, which relies on inherent properties present in certain materials (such as naturally occurring fibers like Nomex® or Kevlar®), flame retardancy involves applying specific chemical treatments onto various fabrics to impart fire-protective properties.

Moreover, the performance of flame-resistant materials remains consistent regardless of exposure to fire, as their inherent characteristics do not diminish over time. In contrast, materials treated with flame retardants may experience a decrease in their fire-resistant properties as these treatments can degrade or become less effective over prolonged use or exposure to environmental factors.

It is important to dispel this difference and recognize that flame resistance and flame retardancy are distinct concepts with unique qualities and applications. By understanding these differences, individuals can make more informed choices when selecting appropriate fire safety measures and products.

Understanding Flame Resistance

Definition and characteristics of flame resistance

Flame resistance refers to the ability of a material to withstand ignition, prevent or slow down the spread of flames, and resist burning when exposed to fire or high temperatures. Unlike materials that readily catch fire and sustain combustion, flame-resistant materials possess properties that inhibit or suppress the ignition process. These materials act as barriers against heat, flames, and combustion byproducts, providing crucial protection in various applications where fire hazards are present.

Materials with inherent flame resistance

Certain materials possess inherent or natural flame resistance due to their chemical composition and physical structure. Examples include Nomex®, Kevlar®, and Modacrylic fibers. Nomex®, manufactured by DuPont™, is a synthetic aramid fiber known for its exceptional heat resistance.

It is widely used in protective clothing for firefighters, military personnel, industrial workers, and other professionals exposed to high-temperature environments. Kevlar®, another aramid fiber manufactured by DuPont™, exhibits excellent flame retardant properties, high tensile strength, and abrasion resistance.

It finds applications in ballistic protection gear (e.g., bulletproof vests), industrial gloves, and aerospace components. Modacrylic fibers are often blended with other textile materials to enhance their flame-resistant properties while maintaining comfort and durability.

Properties that make them naturally resistant to flames

The natural flame resistance of these materials can be attributed to several key properties they possess. High carbon content in aramid fibers like Nomex® and Kevlar® contributes to their thermal stability by resisting degradation under extreme heat conditions.

Additionally, strong intermolecular bonds within the fiber structure promote stability against thermal decomposition at elevated temperatures. The formation of a charred layer on the surface when exposed to flames acts as an insulating barrier that limits further heat transfer into the material, thereby preventing or slowing down the spread of fire.

Modacrylic fibers, on the other hand, contain halogen atoms within their polymer structure, which releases fire-retardant gases when exposed to heat, creating a barrier against flames. These inherent properties make these materials highly effective in protecting individuals or equipment from fire-related hazards.

Exploring Flame Retardancy

When it comes to fire safety, understanding the principles of flame retardancy is crucial. Flame retardants are chemicals that slow down or inhibit combustion, reducing fire spread. These compounds work by interfering with one or more stages of the fire triangle – heat, oxygen, and fuel.

Flame retardant chemicals and their mechanisms

Various types of flame retardant chemicals are available, each with its own mechanism for suppressing flames. One group of commonly used flame retardants is halogenated compounds, such as brominated or chlorinated substances. Halogenated compounds act by releasing halogen radicals when exposed to high heat.

These radicals interrupt the chemical chain reactions involved in combustion and hinder the flame’s ability to sustain itself. Another class of flame retardant chemicals is phosphorus-based compounds.

Phosphorus-containing additives can function through several mechanisms. They may create a protective char layer that acts as a barrier between the material and the flames, reducing further heat transfer.

Additionally, they can dilute flammable gases released during combustion by generating non-combustible gases like carbon dioxide and nitrogen phosphorous compounds. Nitrogen-based compounds also play a significant role in flame retardancy.

Nitrogen can act as a diluent that absorbs heat energy during combustion while simultaneously inhibiting chemical reactions necessary for sustained burning. The choice of specific flame retardant depends on factors such as the type of material being treated, performance requirements, environmental considerations, and regulations pertaining to safety standards.

Key Differences between Flame Resistance and Flame Retardancy

When understanding the distinction between flame resistance and flame retardancy, several crucial differences set them apart. These disparities lie in inherent vs applied protection, performance under extreme conditions, and applications across different industries.

Inherent vs. Applied Protection

The primary difference between flame-resistant materials and flame retardants lies in their mode of fire protection. Flame-resistant materials possess built-in properties that make them naturally resistant to flames without the need for any additional treatments or chemicals. On the other hand, flame retardants are substances that are added to materials during manufacturing processes to enhance their fire resistance capabilities.

Performance under Extreme Conditions

Another significant contrast between flame-resistant materials and flame retardants pertains to their performance when exposed to fire or extreme heat. Flame-resistant materials maintain their protective qualities even after being subjected to intense heat or direct flames.

They continue to provide a barrier against thermal hazards even after exposure, offering valuable protection for individuals wearing such garments or utilizing these materials. In contrast, flame-retardant treatments may gradually degrade over time, especially with repeated exposure or wear and tear.

Applications in Different Industries

The divergence in applications is yet another noteworthy difference between flame resistance and flame retardancy. Flame-resistant materials predominantly find application in professions where individuals face heightened fire risks, such as industrial workers operating in hazardous environments.

The protective clothing designed using these inherently resistant fibers ensures that individuals have an increased chance of escaping injuries caused by flames or heat sources. In contrast, flame retardants primarily find application within the realm of consumer products and everyday items.

These chemicals are often included in the manufacturing processes of furniture, electronics, and building materials to increase their fire resistance. By incorporating flame retardants into these products, manufacturers aim to minimize potential fire hazards that may arise from their usage in various settings.

Common Misconceptions Debunked

Mislabeling of products as “flame resistant” when they are actually treated with flame retardants.

One of the most prevalent misconceptions surrounding flame resistance and flame retardancy is the mislabeling of products. Many consumers assume that if a product is labeled as “flame resistant,” it inherently possesses the qualities of flame resistance.

However, this is not always the case. In reality, some products are actually treated with flame retardant chemicals to enhance their fire resistance properties.

This mislabeling can lead to confusion and a false sense of security for individuals relying on these items for protection from flames. It is essential for manufacturers and regulatory bodies to enforce accurate labeling practices to ensure consumer safety and prevent misleading information.

Lack of standardized testing and certification processes.

Another common misconception surrounding flame resistance and flame retardancy lies in the lack of standardized testing and certification processes. Due to variations in industry standards and regulations, different methods may be employed by manufacturers or organizations to test these properties, leading to discrepancies in product claims and performance evaluations.

Additionally, the absence of uniform certification procedures creates confusion among consumers who seek reliable information about the fire safety attributes of various products. Establishing consistent testing protocols and internationally recognized certifications would enable consumers to make informed decisions while purchasing items that offer genuine flame protection.

Conclusion

Understanding the nuanced differences between flame resistance and flame retardancy is crucial in ensuring effective fire safety measures across industries. While both concepts aim at reducing the risk of fire-related incidents, they possess distinct characteristics concerning inherent protection versus applied treatments. The prevalence of mislabeled products highlights a pressing need for enhanced transparency and accuracy in labeling practices within the marketplace.

Additionally, standardization efforts regarding testing protocols and certifications would provide consumers with reliable information while promoting consistency across industries. By prioritizing these aspects, we can foster a safer environment and empower individuals with the knowledge needed to make informed choices regarding fire safety.

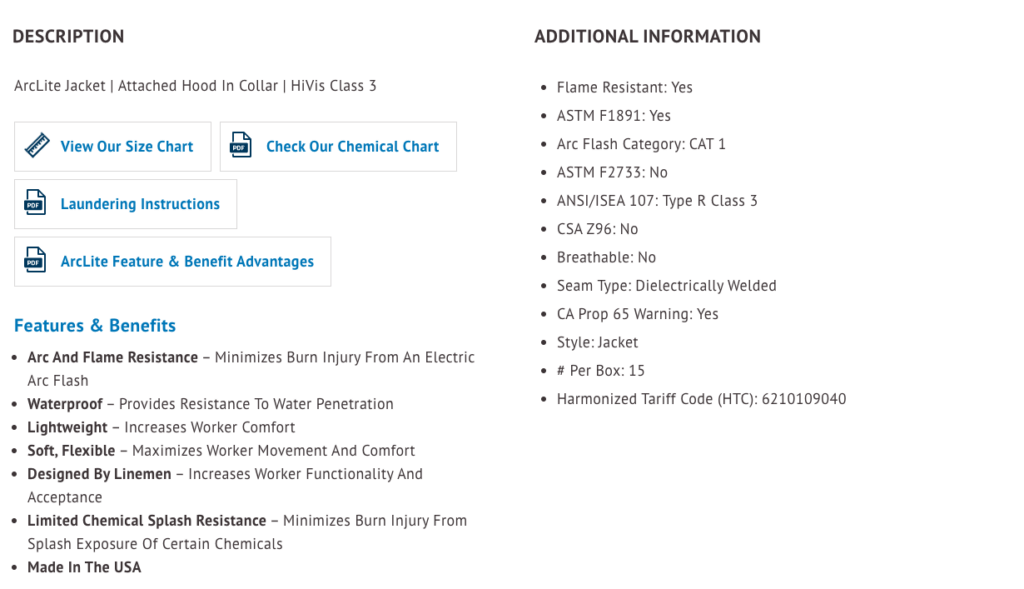

At NASCO Industries, we understand the important role of workers in hazardous conditions. Our FR rain gear is developed and tested to meet or exceed industry standards. At the bottom of each product page, you can find full information on the safety standards for that specific garment we manufacture.

Recent Comments